When selecting wood-based panels for furniture, interior decoration, or construction projects, melamine plywood and traditional plywood are two commonly compared options. While both are widely used and structurally reliable, they differ significantly in surface treatment, performance, applications, and environmental impact. Understanding these differences can help manufacturers, designers, and homeowners make more informed material choices.

Surface Finish and Appearance

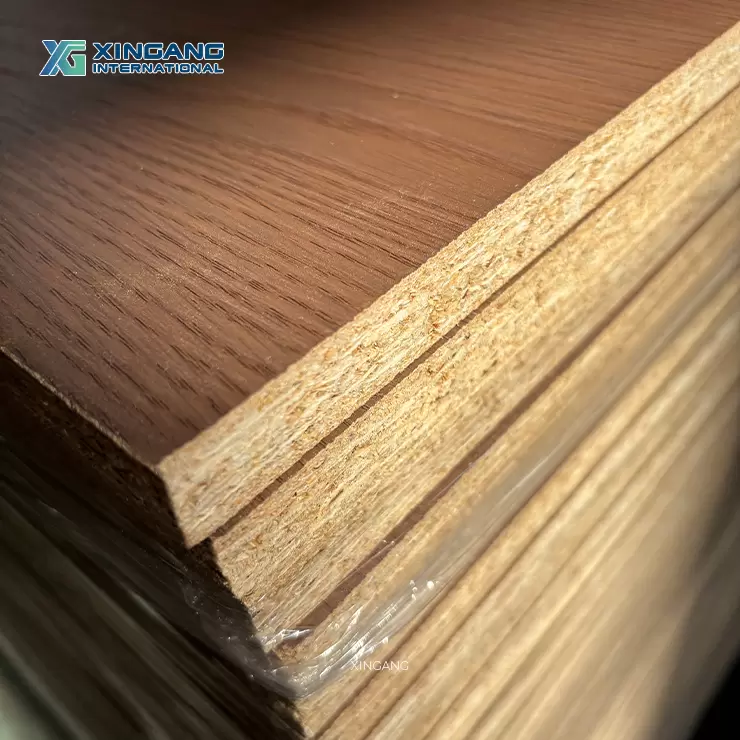

One of the most noticeable differences between melamine plywood and traditional plywood lies in the surface finish. Melamine plywood features a decorative melamine-impregnated paper layer that is bonded to the plywood core under high pressure and temperature. This results in a smooth, hard, and visually consistent surface available in a wide range of colors, wood grains, and textures.

Traditional plywood, on the other hand, typically has a raw veneer surface. To achieve a finished look, it usually requires additional treatments such as painting, laminating, or veneering. This adds extra steps, time, and cost to the production process.

Durability and Wear Resistance

Melamine plywood is known for its excellent resistance to scratches, stains, and heat. The hard melamine surface protects the panel from everyday wear, making it suitable for furniture and interior applications that experience frequent use.

Traditional plywood offers good structural strength but is more vulnerable to surface damage if left untreated. Without protective coatings, it can be easily scratched or stained, especially in high-traffic environments. As a result, traditional plywood often relies on additional finishes to improve durability.

Maintenance and Ease of Use

Another key difference is maintenance. Melamine plywood is easy to clean and requires minimal upkeep. Its non-porous surface allows for quick removal of dirt and spills, making it ideal for kitchens, offices, schools, and commercial interiors.

Traditional plywood generally demands more maintenance, particularly when used in visible or exposed applications. Painted or coated surfaces may need periodic refinishing to maintain their appearance and performance over time.

Cost and Production Efficiency

From a cost perspective, melamine plywood can offer better overall efficiency for finished furniture and interior products. Because it comes with a ready-to-use decorative surface, it reduces the need for secondary finishing processes, lowering labor costs and material waste.

Traditional plywood is often more flexible for custom designs but may involve higher total costs once surface treatments and finishing work are taken into account. The choice between the two often depends on project scale, budget, and design requirements.

Environmental and Health Considerations

Environmental performance has become a major factor in material selection. In the past, some wood-based panels raised concerns due to formaldehyde emissions from adhesives. Today, leading manufacturers are addressing this issue through innovation.

Shandong Xingang Group Co., Ltd. has long been dedicated to the development of environmentally friendly new materials in the wood industry. The company’s proprietary biomimetic adhesive technology contains zero formaldehyde, zero benzene, and no harmful substances. This breakthrough has been successfully applied at scale in biomimetic decorative boards, ultra-thin fiberboards, and biomimetic marine plywood.

By using advanced green adhesive systems, Xingang panels achieve not only superior environmental performance but also antibacterial and antiviral properties, while maintaining excellent mechanical strength. When applied to melamine plywood and related products, these innovations significantly improve indoor air quality and overall user safety.

Application Scenarios

Melamine plywood is widely used in furniture manufacturing, cabinetry, shelving systems, and interior wall panels where aesthetics, durability, and easy maintenance are priorities. Its consistent appearance makes it especially suitable for standardized and large-scale production.

Traditional plywood remains popular in structural applications, custom furniture, and projects that require flexible finishing options. It is often chosen for construction, packaging, and situations where surface appearance is less critical or will be customized later.

Making the Right Choice

Choosing between melamine plywood and traditional plywood depends on the specific needs of a project. If the goal is to achieve a clean, modern look with high durability and minimal maintenance, melamine plywood is often the better option. If flexibility in finishing and structural versatility are more important, traditional plywood may be more suitable.

With continuous innovation in eco-friendly materials, companies like Shandong Xingang Group are narrowing the gap between performance and sustainability. Their commitment to green technology enables both melamine plywood and traditional plywood products to meet higher environmental and health standards.

Conclusion

Melamine plywood and traditional plywood each have their own strengths and ideal applications. Melamine plywood stands out for its decorative surface, durability, and ease of maintenance, while traditional plywood offers flexibility and structural reliability. Backed by environmentally friendly innovations such as Xingang’s biomimetic adhesive technology, modern wood panels are evolving toward healthier, safer, and more sustainable solutions, supporting a greener future for furniture and interior design.

https://www.woodfull.top/

Shandong Xingang Group Co., Ltd.