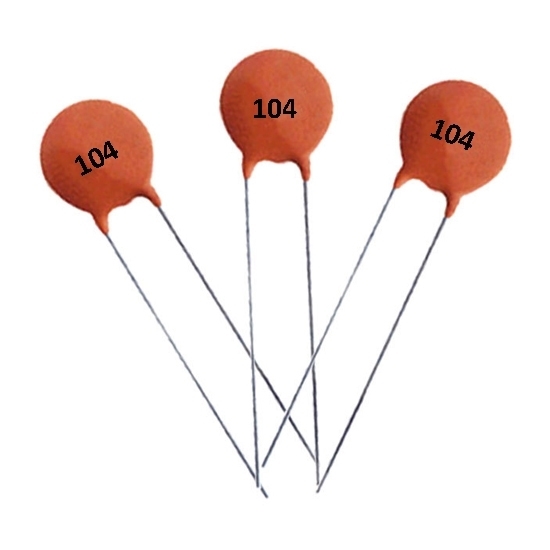

DC motors are widely used in various industries for their efficiency, reliability, and precise control. To optimize their performance, capacitors play a crucial role in ensuring smooth operation, reducing electrical noise, and enhancing overall efficiency. In this article, we will explore why DC motors need capacitors and how they contribute to their improved performance.

- Starting Torque Enhancement:

One of the primary reasons for using capacitors in DC motors is to enhance the starting torque. When a motor starts, it requires a higher torque to overcome inertia and initiate motion. Capacitors provide an additional burst of power during the starting phase, enabling the motor to overcome the initial resistance and accelerate smoothly. This is particularly important in applications where the motor needs to start under heavy loads or in adverse conditions. - Power Factor Correction:

Capacitors also play a vital role in power factor correction for DC motors. Power factor is a measure of how effectively electrical power is utilized. Inefficient power factor can result in increased energy consumption, reduced motor efficiency, and higher utility costs. By adding capacitors, the reactive power drawn by the motor is compensated, leading to improved power factor and reduced energy wastage. This not only benefits the motor's performance but also contributes to a greener and more sustainable operation. - Suppression of Electrical Noise:

DC motors can generate electrical noise during operation, which can interfere with other sensitive electronic devices or communication systems. Capacitors help in suppressing this electrical noise by acting as filters. They absorb and dissipate high-frequency noise generated by the motor, preventing it from propagating through the electrical system. This ensures a cleaner power supply and minimizes the risk of electromagnetic interference, thereby improving the overall reliability and performance of the motor. - Voltage Regulation and Stability:

Capacitors also aid in voltage regulation and stability for DC motors. Fluctuations in the power supply can adversely affect motor performance and lead to premature wear and tear. By adding capacitors, they act as voltage stabilizers, absorbing voltage spikes and surges, and releasing stored energy during voltage drops. This helps in maintaining a consistent voltage level, ensuring smooth and uninterrupted motor operation, and extending the motor's lifespan.

Conclusion:

In conclusion, capacitors play a vital role in enhancing the performance of DC motors. They contribute to improved starting torque, power factor correction, suppression of electrical noise, and voltage regulation. By incorporating capacitors into DC motor systems, industries can achieve higher efficiency, reduced energy consumption, and enhanced reliability. Understanding the importance of capacitors in DC motors allows engineers and technicians to optimize motor performance and ensure smooth operation in various applications.