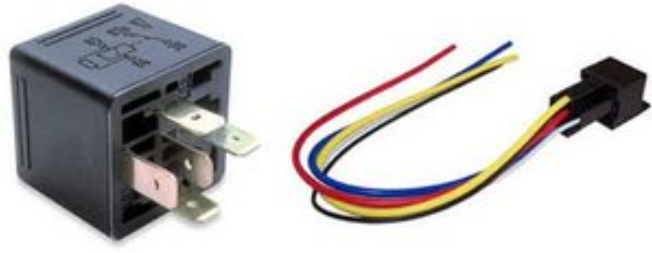

Mechanical relays have been a fundamental component in various industries for decades, providing essential switching capabilities in electrical circuits. However, despite their widespread use, these relays are not without their limitations. In this article, we will delve into the problems associated with mechanical relays, exploring their impact on performance, reliability, and overall system efficiency. Furthermore, we will discuss innovative solutions that address these challenges, paving the way for more advanced and reliable relay technologies.

- Contact Wear and Tear:

One of the primary issues with mechanical relays is contact wear and tear. As relays switch on and off, the contacts experience mechanical stress, leading to gradual degradation. Over time, this can result in increased contact resistance, compromised signal integrity, and even complete failure. Such wear and tear limit the lifespan and reliability of mechanical relays, making them unsuitable for applications requiring long-term operation. - Limited Switching Speed:

Mechanical relays are inherently slow compared to their solid-state counterparts. The physical movement of contacts introduces a significant delay in the switching process, which can be problematic in applications that demand rapid response times. For instance, in high-frequency signal routing or advanced automation systems, the sluggish switching speed of mechanical relays can hinder overall system performance and efficiency. - Electromagnetic Interference (EMI):

Another critical concern with mechanical relays is their susceptibility to electromagnetic interference (EMI). When contacts open or close, arcing can occur, generating EMI that can interfere with nearby sensitive electronic components. This interference can lead to signal distortion, data corruption, or even damage to the relay itself. Mitigating EMI in mechanical relays requires additional circuitry and shielding, adding complexity and cost to the overall system design. - Size and Weight:

Mechanical relays are typically bulkier and heavier compared to solid-state alternatives. This physical limitation restricts their use in applications with space constraints or weight-sensitive environments. Industries such as aerospace, automotive, and portable electronics often require compact and lightweight solutions, making mechanical relays less suitable for these demanding applications.

Solutions and Future Developments:

To overcome the problems associated with mechanical relays, researchers and engineers have been actively exploring alternative technologies. Some of the promising solutions include:

- Solid-State Relays (SSRs): SSRs utilize semiconductor devices, such as MOSFETs or thyristors, to achieve switching without any mechanical movement. These relays offer faster switching speeds, longer lifespan, and improved reliability compared to mechanical relays. However, SSRs may have limitations in high-voltage or high-current applications due to their inherent voltage drop and power dissipation characteristics.

- MEMS Relays: Microelectromechanical systems (MEMS) relays combine the advantages of mechanical and solid-state relays. These miniature devices utilize microfabrication techniques to create tiny mechanical switches, enabling faster switching speeds and reduced contact wear. MEMS relays show great potential in applications requiring high-frequency switching and miniaturization.

- Optically Isolated Solid-State Relays: These relays use optocouplers or optoisolators to provide electrical isolation between input and output circuits. By eliminating physical contact, optically isolated solid-state relays offer enhanced reliability, reduced EMI, and improved safety in high-voltage applications.

Conclusion:

While mechanical relays have served as reliable switching components for many years, their limitations in terms of contact wear, switching speed, EMI, size, and weight have prompted the exploration of alternative technologies. Solid-state relays, MEMS relays, and optically isolated solid-state relays are among the innovative solutions that address these challenges. As technology continues to advance, these alternatives hold the promise of overcoming the problems associated with mechanical relays, enabling more efficient and reliable systems across various industries.