The safe disposal of medical waste is a critical responsibility for healthcare facilities, laboratories, and specialized waste treatment centers. Infectious materials, pharmaceutical residues, and hazardous chemicals require reliable treatment methods that meet strict environmental and health regulations. Selecting the right incinerator for medical waste disposal is therefore a strategic decision that directly affects compliance, operational efficiency, and long-term costs.

This article explores the key features, capacity requirements, and cost considerations involved in choosing an incinerator for medical waste disposal, while highlighting how professional manufacturers such as Aoli Environmental Protection Technology Co., Ltd. support complex waste treatment needs.

Understanding Your Medical Waste Treatment Requirements

Before selecting an incinerator, it is essential to clearly understand the type and volume of medical waste generated. Medical waste may include infectious waste, pathological waste, pharmaceutical waste, and chemical residues, each requiring specific treatment conditions.

An effective incinerator for medical waste disposal must be capable of handling variable waste compositions while ensuring complete destruction of harmful substances. Accurate waste characterization helps determine the appropriate incineration technology and system configuration.

Key Features of a Reliable Medical Waste Incinerator

A high-quality incinerator for medical waste disposal integrates multiple technical features designed to ensure safety, efficiency, and regulatory compliance.

High-Temperature and Stable Combustion

Medical waste incinerators must maintain consistently high temperatures to destroy pathogens and hazardous compounds. Advanced combustion control systems ensure stable operation even with fluctuating waste loads.

Pyrolysis and Advanced Thermal Treatment

Medical waste pyrolysis incinerators operate under controlled oxygen conditions, improving combustion efficiency and reducing secondary pollution. This technology is particularly effective for complex medical and hazardous waste streams.

Advanced Flue Gas Treatment Systems

Effective exhaust gas treatment is essential for meeting emission standards. Modern systems incorporate multi-stage gas cleaning processes to minimize particulate matter, acidic gases, and harmful byproducts.

Automation and Safety Control

Automated feeding, temperature control, and monitoring systems reduce operational risks and improve consistency, making incinerators safer and easier to operate.

Determining the Right Capacity

Capacity selection is one of the most important decisions when choosing an incinerator for medical waste disposal. An undersized system can lead to operational bottlenecks, while oversized equipment increases capital and operating costs.

Key capacity-related factors include:

-

Daily and peak medical waste generation volumes

-

Operating hours and required throughput

-

Future expansion plans

-

Waste storage limitations

A professional manufacturer can help analyze these parameters and recommend an incinerator capacity that balances performance and cost efficiency.

Cost Considerations: Initial Investment and Long-Term Value

The cost of an incinerator for medical waste disposal extends beyond the initial purchase price. While upfront investment is important, long-term operating costs often have a greater impact on total cost of ownership.

Key cost factors include:

-

Energy consumption and fuel efficiency

-

Maintenance and spare parts requirements

-

Emission control and compliance costs

-

System lifespan and reliability

Incorporating heat recovery equipment can significantly reduce operating costs by capturing and reusing thermal energy generated during incineration.

Aoli Environmental Protection Technology Co., Ltd.: A Trusted Incinerator Manufacturer

Aoli Environmental Protection Technology Co., Ltd. is a professional incinerator manufacturer with extensive experience in thermal treatment solutions for organic waste gas, organic waste liquid, hazardous chemical waste, and medical waste. The company offers a comprehensive product range designed to meet diverse industrial and healthcare waste treatment needs.

Aoli’s main products include:

-

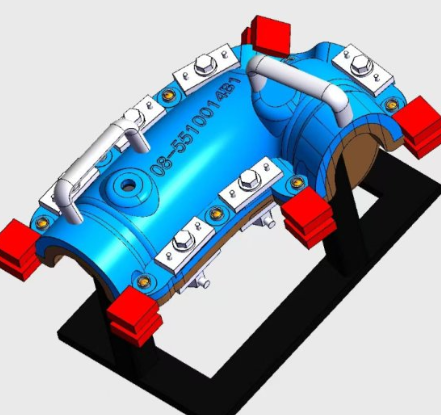

Medical waste pyrolysis incinerators

-

Process waste incinerators

-

Waste liquid incinerators

-

Waste gas incinerators

-

Regenerative thermal oxidizers (RTO)

-

Hazardous waste rotary kiln incinerators

-

Thermal energy recovery systems

By combining advanced engineering, reliable materials, and customized system design, Aoli provides incineration solutions that deliver stable performance and long-term environmental compliance.

Making an Informed Decision

Choosing the right incinerator for medical waste disposal requires a careful evaluation of technical performance, capacity requirements, regulatory standards, and lifecycle costs. Partnering with an experienced manufacturer ensures that the selected system is tailored to specific waste profiles and operational conditions.

With its focus on advanced thermal treatment technologies and environmental responsibility, Aoli Environmental Protection Technology Co., Ltd. helps healthcare facilities and waste management operators implement safe, efficient, and compliant medical waste disposal solutions.

Conclusion

The right incinerator for medical waste disposal is essential for protecting public health, meeting regulatory requirements, and achieving cost-effective waste management. By understanding key features, selecting the appropriate capacity, and considering long-term operating costs, organizations can make informed investment decisions.

As a professional incinerator manufacturer, Aoli Environmental Protection Technology Co., Ltd. offers a full range of solutions for medical waste and hazardous waste treatment, supporting safer healthcare operations and sustainable environmental management.

www.jsalfsl.com

Jiangsu Aoli Environmental Protection Technology Co., Ltd.